Electrostatic Flocking: One of Six Key Advantages

Published Date

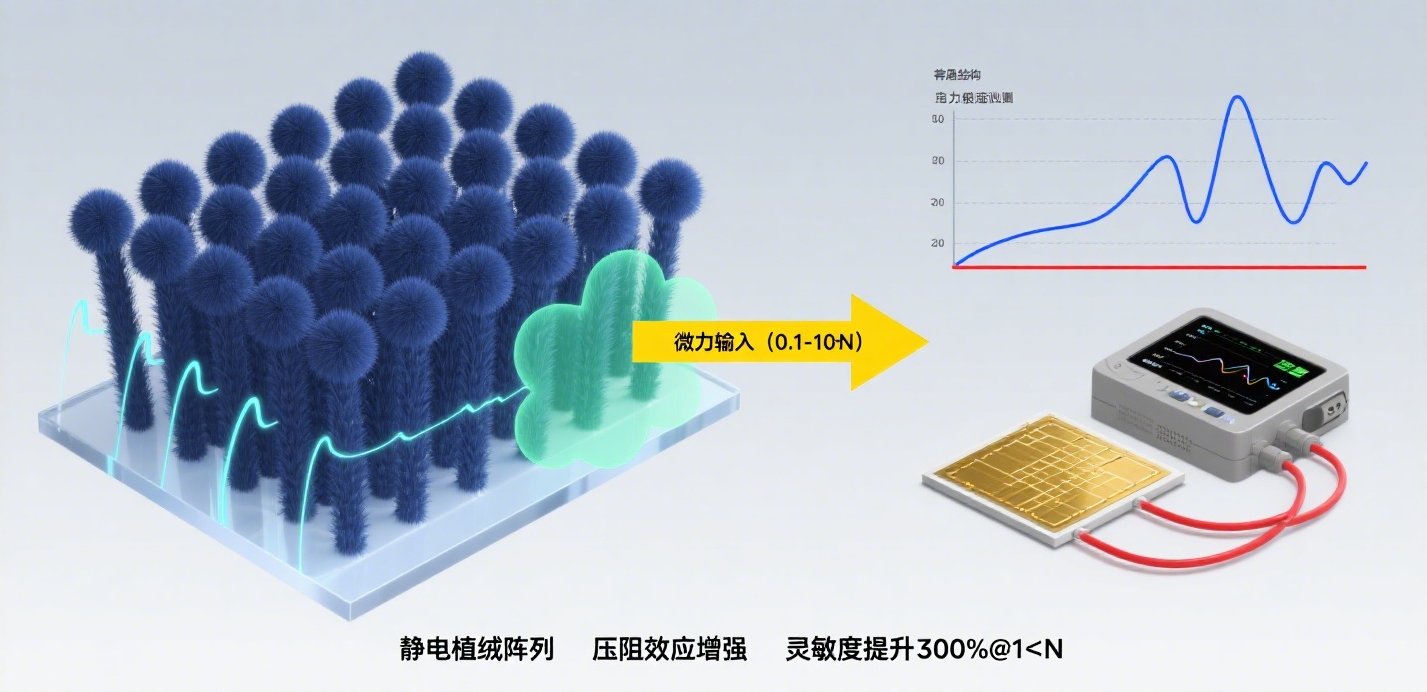

The term “flock” refers to a flocked fiber cluster structure char acterized by a large specific surface area and extremely light weight. The high aspect ratio of the fluff gives the structure high responsiveness. This property enable the fiber cluster to respond to subtle external airflows and vibrations like the sen sory hairs of spiders,[31–33] leading to significant angular deflec tions for tiny forces through bending, tilting, and other actions (Figure a).[14,31,34,35] Barth et al.[36] perceived that sensor hair arrays featuring diverse lengths exhibit distinct amplitudes of oscillationinresponsetoairflow oscillation (Figure b), thereby enabling the sensory cells to discern and interpret these varia tions effectively. Due to the excellent response sensitivity to subtle formation, electrostatic flocking can be significantly utilized for airflow, sound and other microforce sensing applications like microex pression.[13,14,37,38] Furthermore, Liu et al.[34] demonstrated that an enhanced transfer of acoustic energy from the atmosphere to the fiber array occurs when the angle of deviation between the f ibers and the vertical axis is beneath 15°.[34] In light of this, elec trostatically flocked surfaces with vertical orientation fibers own the superiority in low airflow velocity detection limit and fast response time.[13,14] The principle of the bionic airflow sensor, made using electrostatic flocking, is as follows.[14] The resistance of the sensor consists of two main components. One is the resis tance from the substrate (Rs), and the other is the contact resis tance (Rc) formed by the CFs touching each other. Whether the sensor is low-density flocked or high-density flocked, the sensing effect of this sensor is achieved by the bending and leaning of the f locked carbon fibers by minute airflow, which change the con tact points between the fibers. This results in changes in the resistance of the upper layer which in turn affects the sensor net work’s current (Figure c).

According to Barth et al.[35] insects have sensory hairs that are madeupofadiverse range of fibers with different lengths. These f ibers work together to form an intricate sensory system that allows insects to accurately perceive a wide range of stimuli, improving the complexity and adaptability of their natural sen sory apparatus.[35,36] Moreover, the increased control over hair length provided by electrostatic flocking technology allows for accurate reproduction of insect sensory hair parameters. Therefore, constructing sensors with arrays of varying fluff lengths using electrostatic flocking presents an exciting avenue for exploration. This approach introduces an additional dimen sion of feasibility for developing sensors of enhanced accuracy, heralding a new prospect for the future of high-resolution sen sory technology.

References:

[13] C. Shen, S. Sun, H. Zhang, Z. Zhang, Adv. Mater. Technol. 2022, *8*

[14] Mater. Horiz. 2022, *9*

[31] P. Fratzl, F. G. Barth, Nature 2009, *462*

[32] F. G. Barth, A Spider's World: Senses and Behavior, Springer, Berlin, Germany, 2002

[33] J. T. Albert, O. C. Friedrich, H. E. Dechant, F. G. Barth, J. Comp. Physiol. A 2001, *187*, 303

[34] Liu Yufeng, Li Yueqiang, Novoselov K. S., Fu Si, Extreme Mech. Lett. 2024, *70*, 102171

[35] F. G. Barth, Naturwissenschaften 2000, *87*

[36] F. G. Barth, U. Wastell, J. A. C. Humphrey, R. Devarakonda

Excerpt from the paper "Electrostatic Flocking: Reborn to Embrace Multifunctional Applications"

Link: https://doi.org/10.1002/sstr.202500143