How to strengthen product competitiveness and improve user experience

Quickly and effectively empower your products

Full adaptation from substrate to requirements

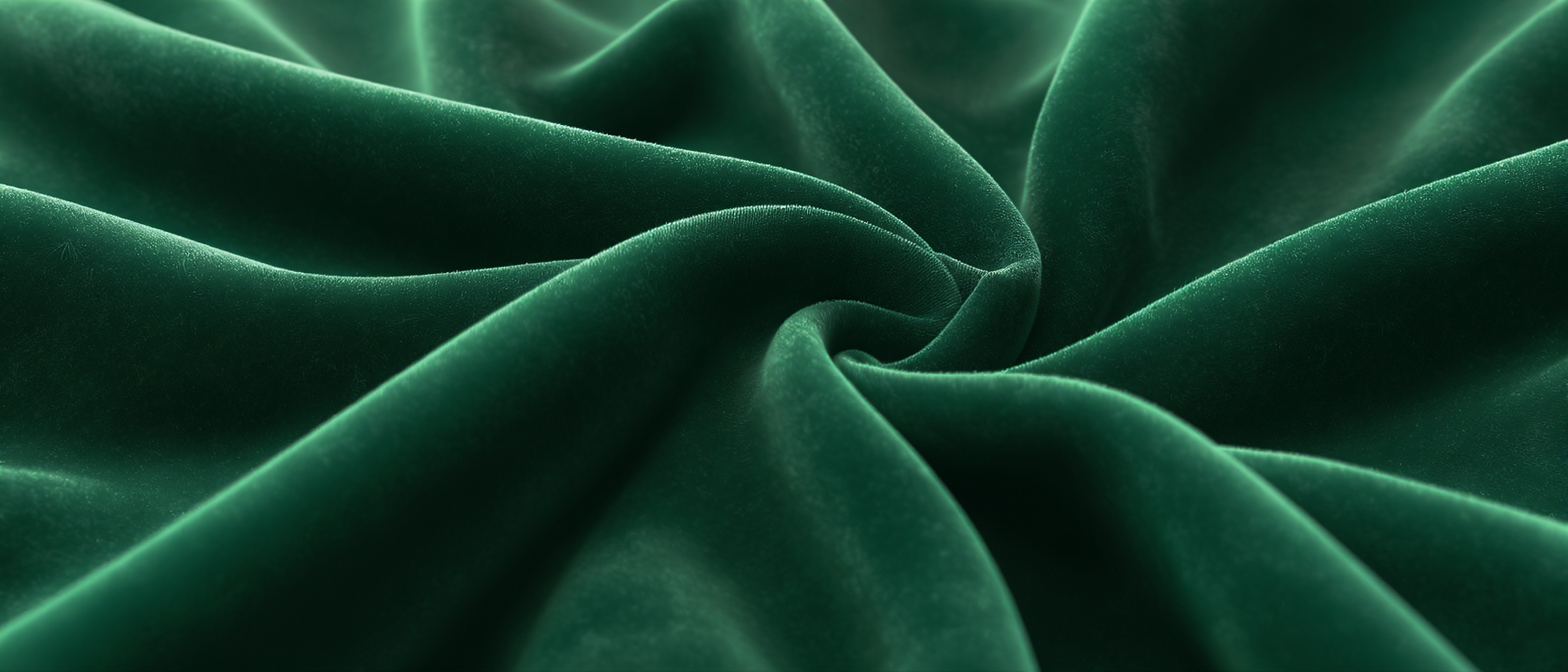

Superior fluff firmness and delicate texture

Full-chain low-carbon from raw materials to processes

Flocking + X, unlocking new surface effect possibilities

Cost-effectiveness benchmark of automated production

The founder has been deeply involved in the flocking industry for 30 years, with deep understanding of the industry and always grasping cutting-edge trends and technological innovation directions

The founder has years of experience in upstream raw material (fluff) enterprises and is quite proficient in flocking raw materials

Currently the only enterprise in the global flocking industry with flocking production capabilities in all three dimensions: point, line, and surface

Equipped with a high-quality R&D team led by senior industry experts, dedicated to flocking new material development, process innovation and testing certification, with an average of 10+ patent conversions per year

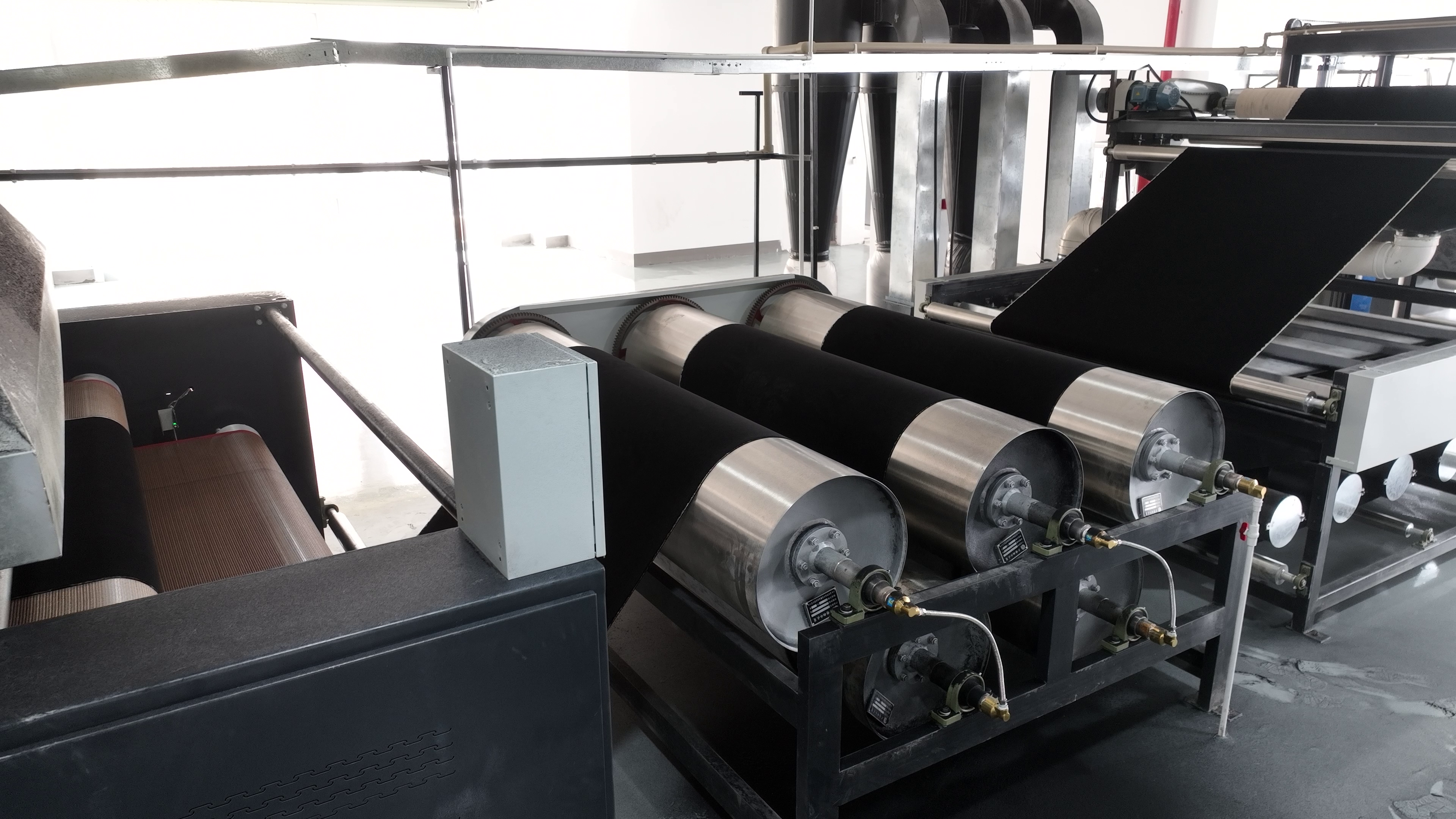

More than 10 leading industry large-scale fully automated flocking production lines with strong size and specification compatibility, enabling customized and large-scale mass production

Based on partner needs, we can provide diversified cooperation models such as OEM standardized production or ODM customized development

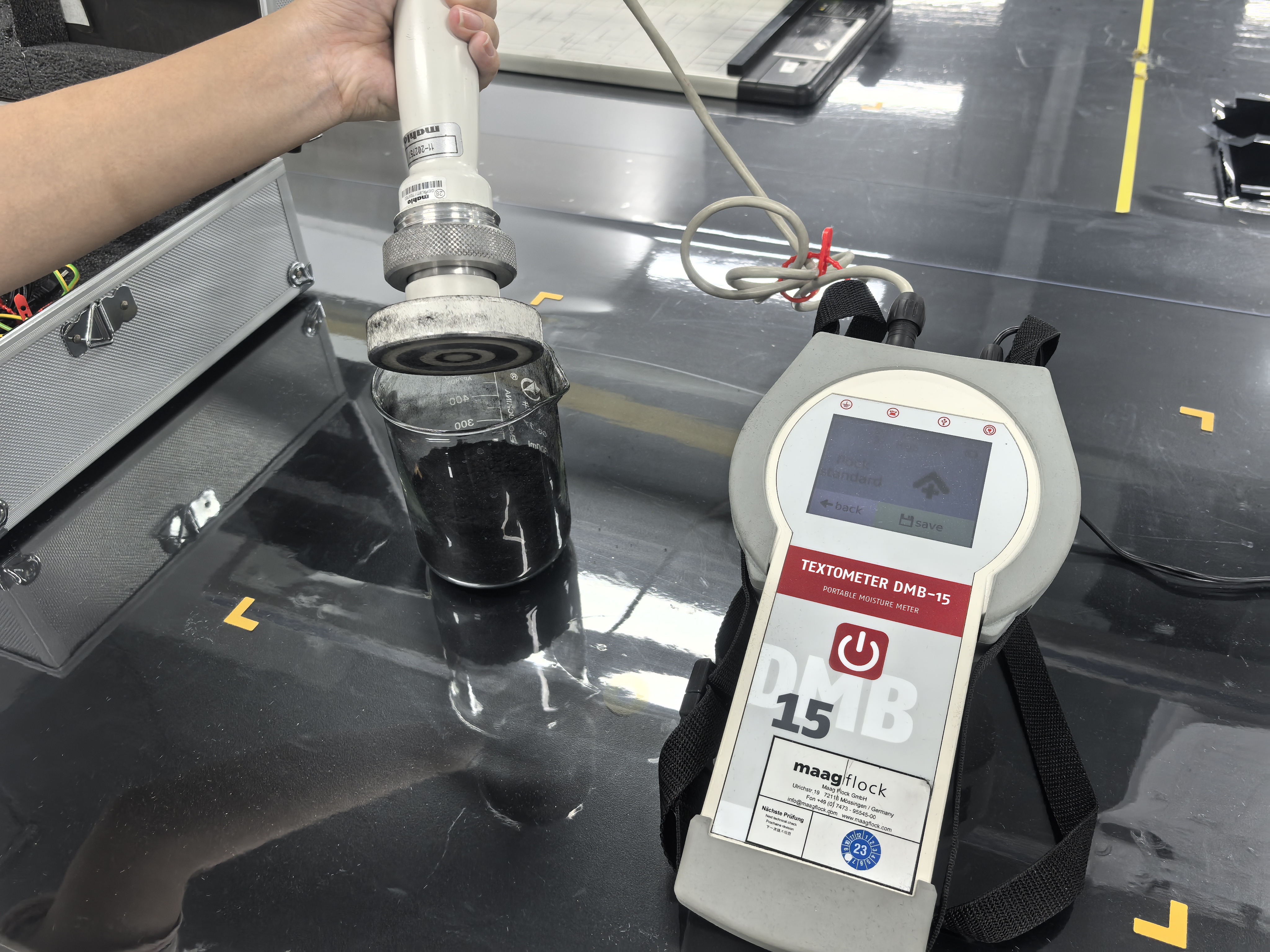

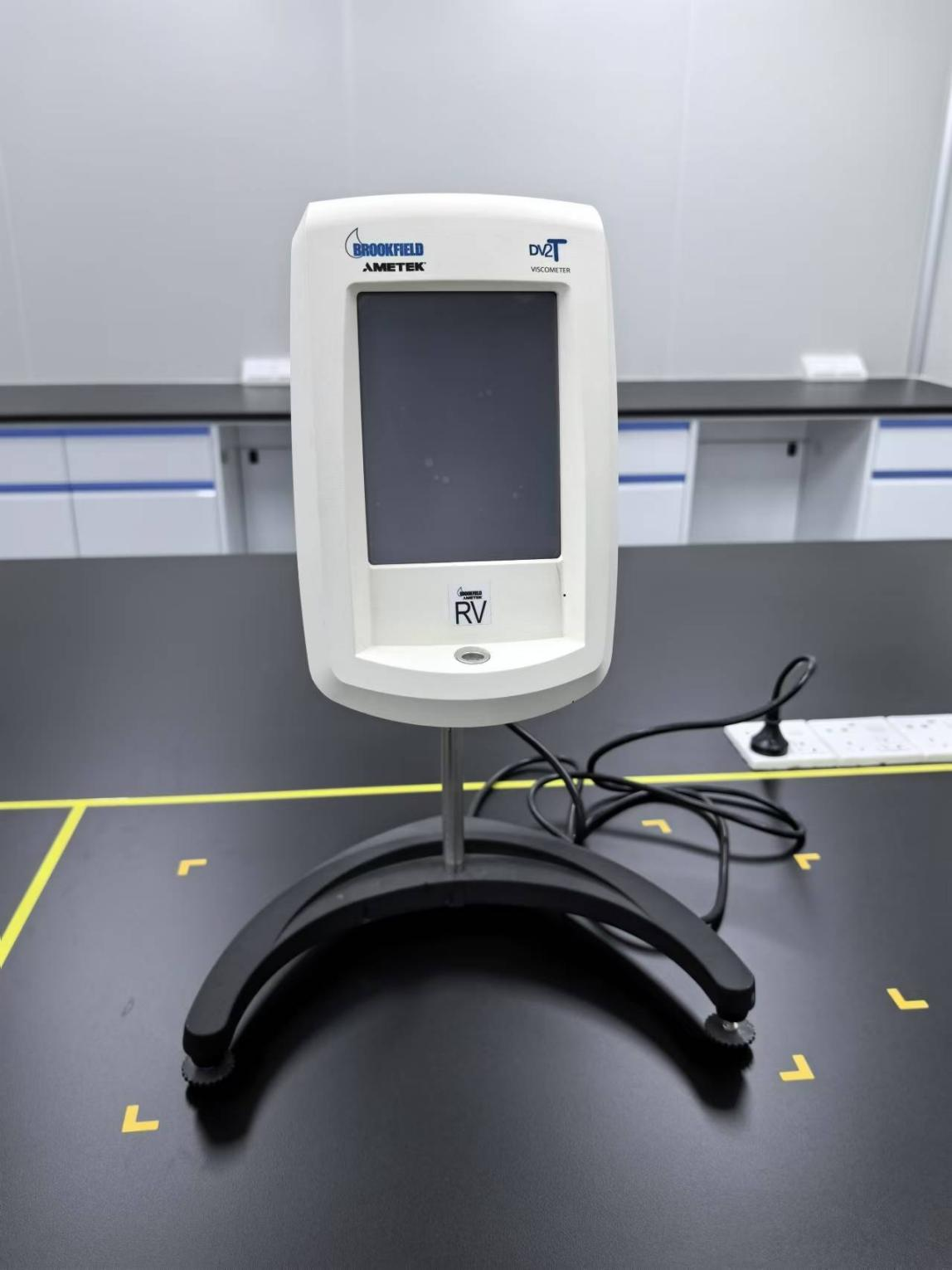

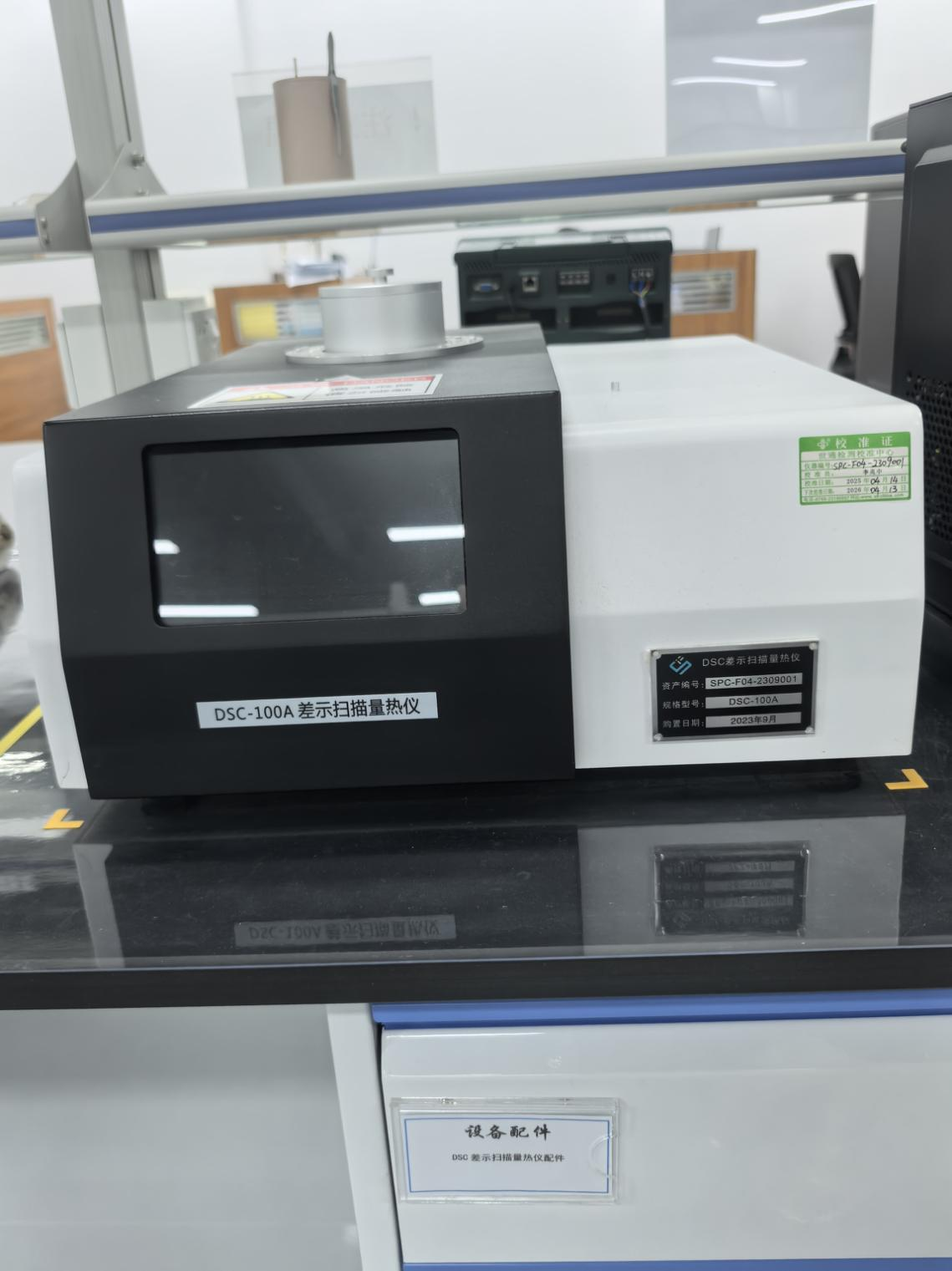

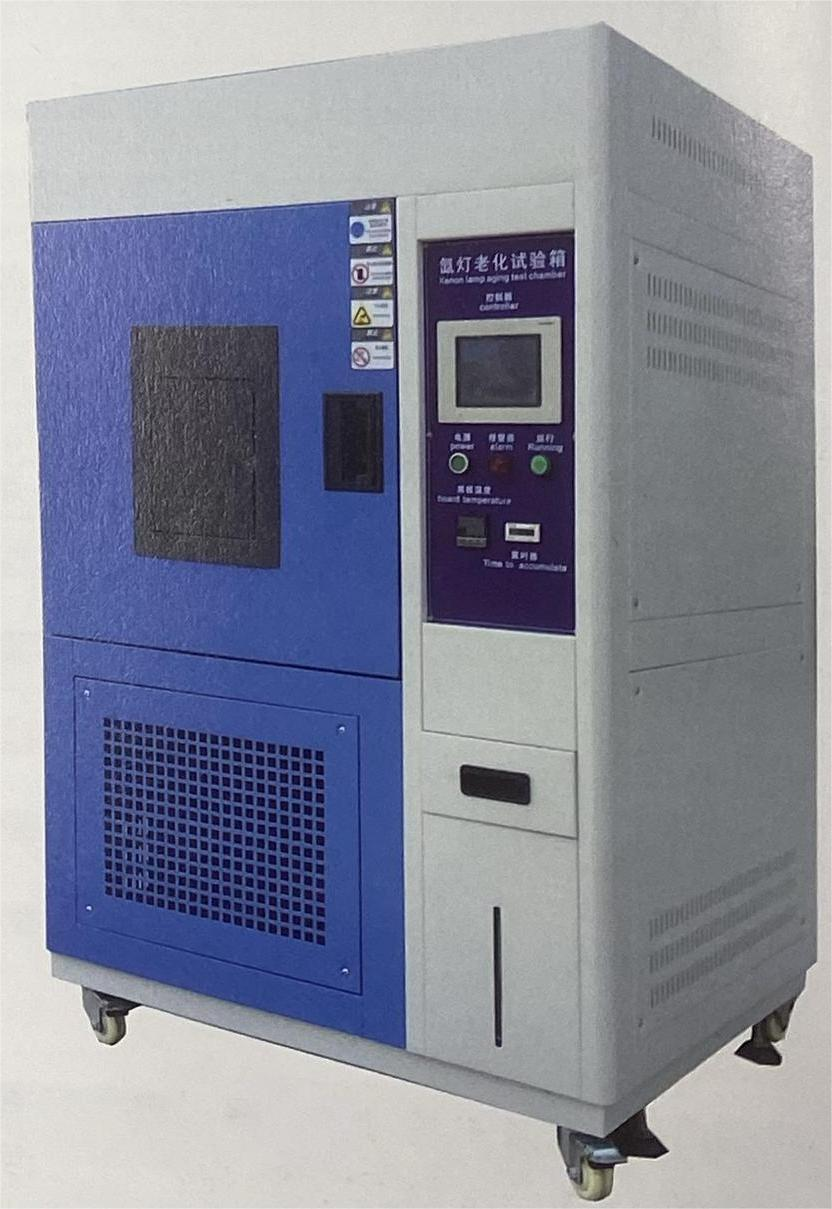

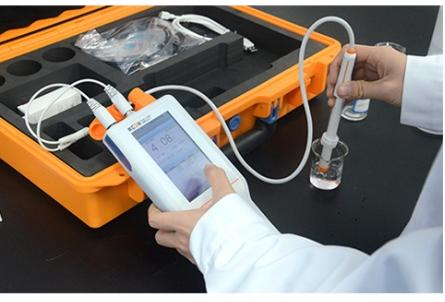

Specialflocking Research Center, with a total investment exceeding 20 million yuan and an area of approximately 1,500㎡. Built far above industry standards, it plans eight professional laboratories: comprehensive testing room, constant temperature and humidity room, precision instrument room, oxidation resistance test room, high temperature room, material laboratory, sample production room, and comprehensive material room to meet different R&D needs.

The center brings together a high-quality R&D team led by senior industry experts and is equipped with world-class experimental equipment, aiming to enhance technological innovation capabilities and R&D efficiency with "innovation-driven, precision testing" as the core.

Core R&D team consists of more than ten professionals with bachelor's and master's degrees, covering key disciplines such as materials science, chemical engineering, and mechanical design.

The team has applied for more than 20 flocking-related utility models and invention patents, with annual R&D investment accounting for 7%.

Technical leader has 20 years of industry experience, proficient in chemical, materials and textile fields.

Electrostatic flocking is a production process that utilizes the physical principle of "like charges repel, opposite charges attract." By establishing a strong electric field through a high-voltage power supply, it drives negatively charged flock fibers to adhere uniformly onto an adhesive-coated substrate. This technique offers advantages such as simple processing, low cost, and unique decorative effects (e.g., velvety or embroidered textures), making it widely applicable in artistic decoration, automotive interiors, packaging, handicrafts, home textiles, and other fields. The core process involves multiple physical mechanisms, including fiber charging, electric field interaction, and adhesive curing, positioning it as a key technology in surface treatment and decorative applications.

Electrostatic flocking technology boasts a long history, with its origins tracing back to 1000 BC in China. In early times, short fibers were adhered to substrates manually or through gravity sedimentation, but this method suffered from issues of disordered fiber orientation. In modern times, electric fields have been applied to electrostatic flocking, enabling precise control over the process.

Thermal interface materials (TIMs) are soft and compliant substances that enhance heat transfer to heat sinks by filling gaps between electronic components.

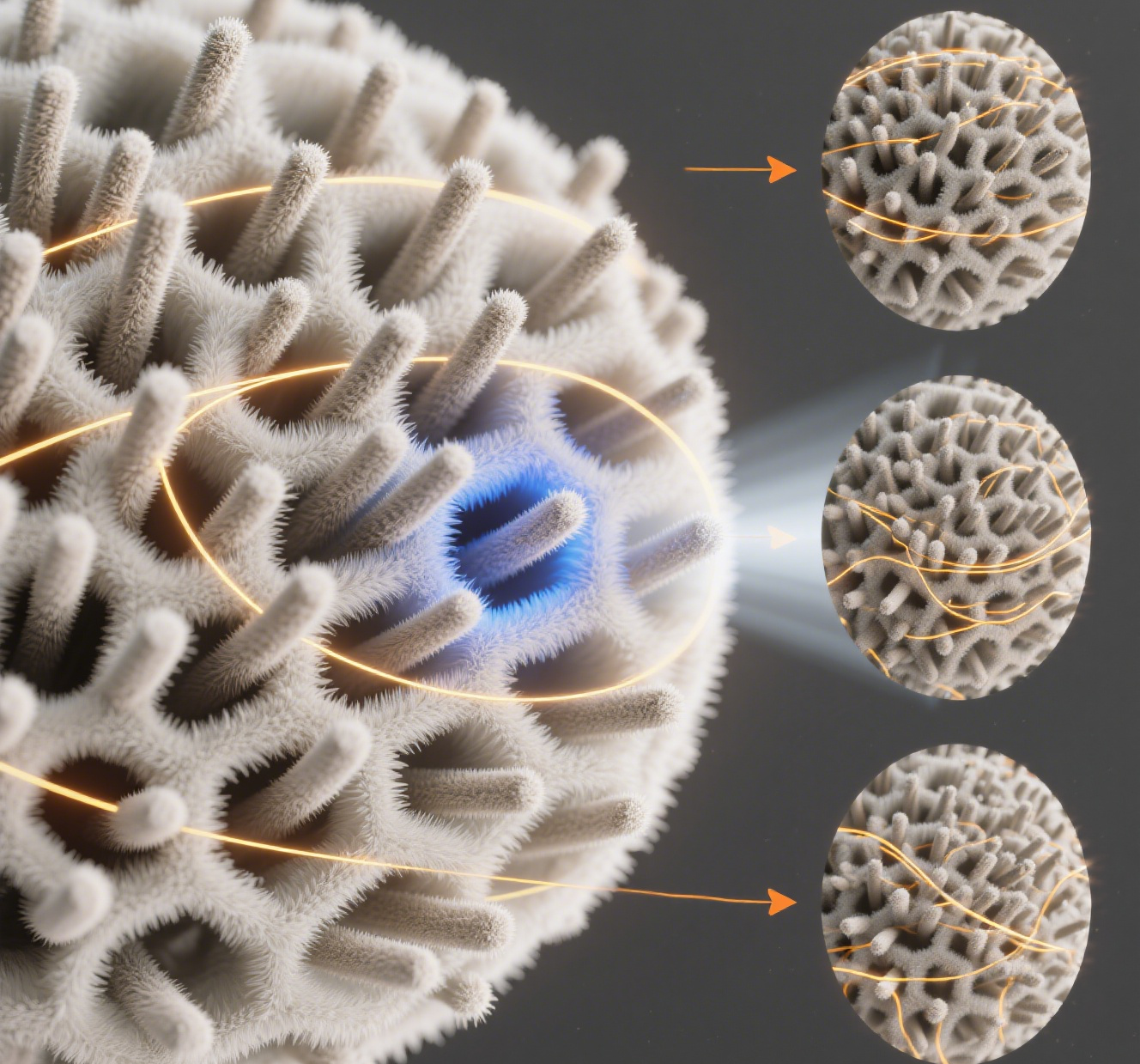

In tissue engineering, scaffolds serve to simulate the authentic in vivo microenvironment, prompting cell differentiation into specific tissues.

A solar interfacial evaporator is a device that converts abundant solar energy into localized thermal energy for producing clean water.

Due to its high specific surface area and conductivity, electrostatic flocking technology demonstrates significant potential in manufacturing three-dimensional batteries. These three-dimensional electrodes can be used in fields such as supercapacitors, wearable devices, sensors, and other applications, characterized by high energy density and exceptional cycling longevity, offering a novel approach for producing high-performance electrodes.

——压力传感器封面.png)

Sensors (Part 2) — Pressure Sensors

In 2018, Zheng et al. utilized electrostatic flocking technology for the first time to fabricate a Salvinia-like structure, successfully mimicking a hairy and elastic surface.

——气流传感器封面.png)

In addition to traditional applications in industries such as automotive parts, home decor, crafts, and packaging, electrostatic flocking technology has been increasingly applied in various functional fields in recent years. These applications include, but are not limited to, airflow sensors, tissue engineering scaffolds, drag reduction in transportation and liquid transfer, solar-driven water evaporators, and 3D electrodes, signifying a major advancement in the functional development of this field.

Electrostatic flocking technology is transitioning from traditional manufacturing to an emerging key method for producing advanced functional materials, leveraging its unique advantages of low cost and high-precision construction of aligned microstructures.

Enhance Mechanical Performance

Implementation of Anisotropic Surfaces

Improve Surface Roughness

Enhanced internal reflection and overall absorption capacity