Electrostatic Flocking: Top 6 Advantages - Advantage 3

Published Date

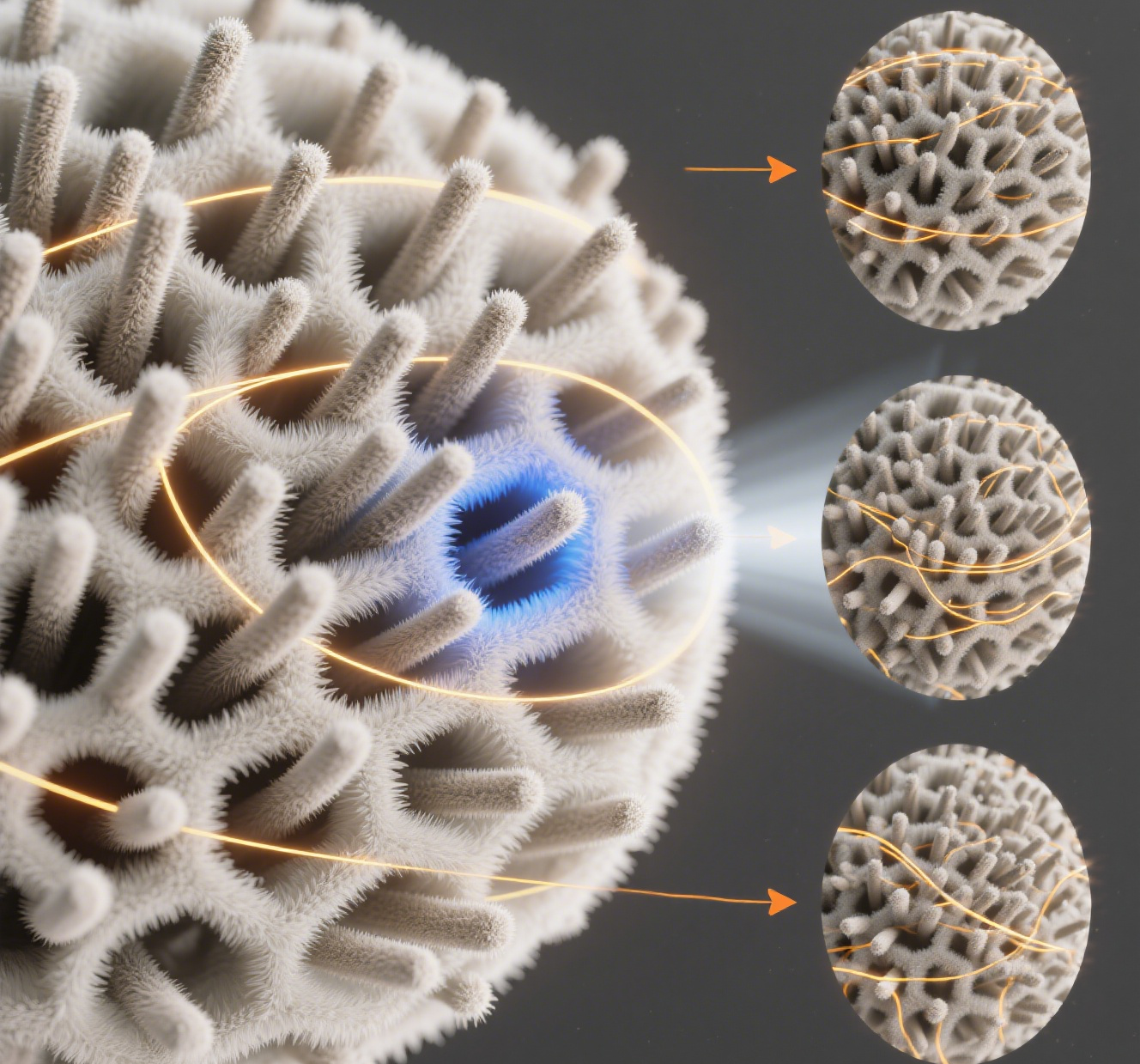

The electrostatic flocking process enables vertical fiber alignment on surfaces, primarily at 90° angles (Figure a).This arrangement facilitates the penetration of incident light into the carbon fiber array, where it undergoes multiple internal reflections, thus enhancing the light-trap effect, as illustrated in Figure 6b,[45] promoting energy absorption.[11] As a result, this produces a blackbody surface through minimal reflectivity and maximal overall absorption. Sekii et al.[47] fabricated a black sur face with carbon fiber which showed that the reflectance of the carbon fiber-flocked surface was over an order of magnitude lower compared to a black surface coated with black paint. This outstanding performance in reflectance makes electrostatic f locking well-suitable for sunlight capture devices like solar driven steam generators.[11,12] Moreover, similar to the increased in internal light reflection on the flocked surface, the multiple internal reflections within the array of short fiber scaffolds significantly contributes in atten uation of electromagnetic waves (Figure 6c).[48] Vertical arrays are commonly used in microwave shielding and are highly effective in enhancing overall microwave absorption.[49,50]

a) Scattering angle distribution of microporous photonic crystals (mPCFs) with varying lengths relative to the substrate. The azimuthal angle between fibers and the substrate's horizontal reference line is defined as "γ"; Reprinted with permission. [19] Copyright © 2019, Springer Science+Business Media, LLC, part of Springer Nature.

b) Light-trapping effect on carbon fiber flocked surfaces; Reprinted with permission. [45] Copyright © 2024, American Chemical Society.

c) Schematic of multi-synergistic shielding mechanism; Reprinted with permission. [48] Copyright © 2020, Elsevier Ltd. Modified surface roughness.

d) Cross-sectional view upon tactile electrode contact; Reprinted with permission. [54] Copyright © 2019, The Author(s).

e) Static vs. dynamic friction characteristics of flocked electrodes with 1.2 mm fiber length; Reprinted with permission. [7] Copyright © 2024, The Author(s).

f) Wenzel model.

g) Cassie-Baxter model.

h) Optical images and schematic diagrams of water droplets on PDMS-modified sample surfaces; Reprinted with permission. [58] Copyright © 2022, Elsevier B.V.

i) Contact angle comparison among non-textured, mesh-patterned, and flocked surfaces; Reprinted with permission. [59] Copyright 2023, The Author(s), under exclusive licence to Springer-Verlag London Ltd., part of Springer Nature.

References:

[11] Guo Yu, Javid M., Li Xiang, Zhai Si, Cai Zhe, Xu Bin, Adv. Sustainable Syst. 2020, *5*

[12] Tu C., Cai W., Chen X., Ouyang X., Zhang H., Zhang Z., Small 2019, *15*, 1902070

[45] Tian Yu, Jiang Yu, Zhu Ran, Yang Xiang, Wu Dong, Wang Xu, Yu Jie, Li Yu, Gao Tao, Li Feng, Environ. Sci. Technol. 2024, *58*

[47] Sekii Y., Hayashi T., IEEE Trans. Dielectr. Electr. Insul. 2009, *16*

[48] Chen X., Gu Y., Liang J., Bai M., Wang S., Li M., Zhang Z., Compos. Part A 2020, *139*

[49] Shen Z., Feng J., ACS Sustainable Chem. Eng. 2019, *7*

[50] Song W.-L., Cao M.-S., Fan L.-Z., Lu M.-M., Li Y., Wang C.-Y., Zhu H.-F., Carbon 2014, *77*

[58] Zhang L., Huang Z., Cai W., Xue X., Min X., Zhang H., Zhang Z., Prog. Org. Coat. 2023, *174*

[59] Feng K., Ni J., Zhang H., Lu D., Int. J. Adv. Manuf. Technol. 2023, *129*

Excerpt from the paper "Electrostatic Flocking: Reborn to Embrace Multifunctional Applications"