Electrostatic Flocking: Top 6 Advantages - Advantage 2

Published Date

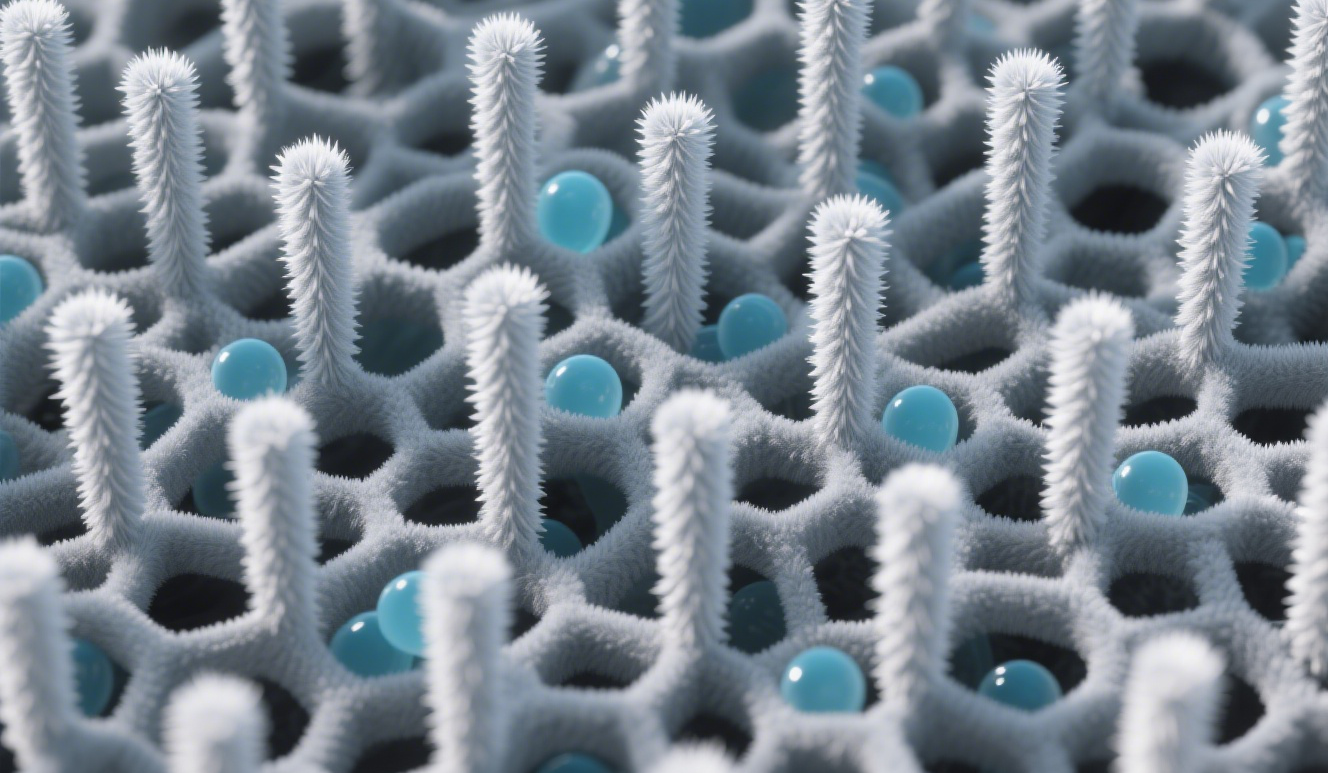

Due to its unique structure, which consists of countless fine f ibers arranged perpendicularly to the base surface, the velvet surface formed by electrostatic flocking overcomes the limita tions of 2D materials in terms of specific surface area. The sur face formed by electrostatic flocking has high verticality (Figure a) and uniformity (Figure b,c), where multiple and uni formly sized pores can be observed from the top (Figure b). Consequently, electrostatic flocking products exhibit a porous appearance with a significantly enlarged specific surface area. In tissue engineering, high and open porosity structures are vital for cell migration, nutrient exchange, and extracellular matrix formation,[39,40] supporting biological processes and making them ideal as scaffolds (Figure d)[41] or for algae culture.[42] The trapped air in pores also enhances their functionality and application potential (Figure e).[43] Additionally, porous structure usually exhibits large specific surface area which is also beneficial for the supercapacitors. During the fabrication of supercapacitors, the high specific surface area associated with electrostatic flocking contributes to an expanded electrochemical surface area of the active materials (Figure f). More electrochemical active sites are the result of this improvement, which also lowers the ionic transport resistance between the active materials and the electro lyte.[9] Moreover, large specific surface area of the micrometer array of microfibers favors higher loading, which leads to more hydrogels adhering to the surface, thereby improves the ability of the inhibition of marine microorganisms, reported by Chen and colleagues.[44] Also, the porous structure makes the light path more complex, increasing the chance of light absorption between the flocks.[11,12] This feature has significant applications in solar devices like solar-driven steam generators.[10,45]

a) Side view of the flocked fiber scaffold demonstrating the highly vertical alignment of electrostatic flocking fibers; Reprinted with permission. [48] Copyright © 2020, Elsevier Ltd.

b) Top view of the flocked fiber scaffold exhibiting high porosity characteristics under electrostatic interaction. [44] Copyright © 2021, American Chemical Society.

c) Distribution of nearest-neighbor fiber spacing in flocked scaffolds; Reprinted with permission. [40] Copyright © 2016, Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

d) Cell growth within pores of the honeycomb scaffold; Reprinted with permission. [24] Copyright © 2015, Royal Society of Chemistry.

e) Air entrapped within the pores of the scaffold.

f) Schematic illustration of the fabrication and structure of a bifunctional asymmetric solid-state supercapacitor; Reprinted with permission. [104] Copyright © 2020, Elsevier B.V.

References:

[9] Meng Lu, Li Ming, Int. J. Energy Res. 2022, *46*

[10] Adv. Funct. Mater. 2024, *34*

[11] Guo Yu, Javid M., Li Xiang, Zhai Si, Cai Zhe, Xu Bin, Adv. Sustainable Syst. 2020, *5*

[12] Tu C., Cai W., Chen X., Ouyang X., Zhang H., Zhang Z., Small 2019, *15*, 1902070

[39] A. Walter, B. Hoyer, A. Springer, B. Morozic, T. Hanke, C. Cherif, W. Pompe, M. Gelinsky, Materials 2012, *5*

[40] E. Gosla, R. Thöndorf, A. Bernhardt, M. Kristen, R. D. Hand, D. Aibibu, C. Cherif, M. Gelinsky, Acta Biomater. 2016, *44*

[41] A. Walter, A. Bernhardt, W. Pompe, M. Gelinsky, B. Morozic, G. Hoffmann, C. Cherif, H. Berthel, W. Richter, G. Schmauch, Text. Res. J. 2007, *77*

[42] Zhang L., Chen L., Wang J., Chen Y., Gao X., Zhang Z., Liu T., Bioresour. Technol. 2015, *181*, 136

[43] Bing W., Wang H., Tian L., Zhao J., Jin H., Du W., Ren L., Small Struct. 2021, *2*(2)

[44] Ren X., Guo M., Xue L., Zeng Q., Gao X., Xin Y., Xu L., Li L., Adv. Eng. Mater. 2020, *22*

Excerpt from the paper "Electrostatic Flocking: Reborn to Embrace Multifunctional Applications"

Link: https://doi.org/10.1002/sstr.202500143