Summary and Prospects of High-Voltage Electrostatic Flocking

Published Date

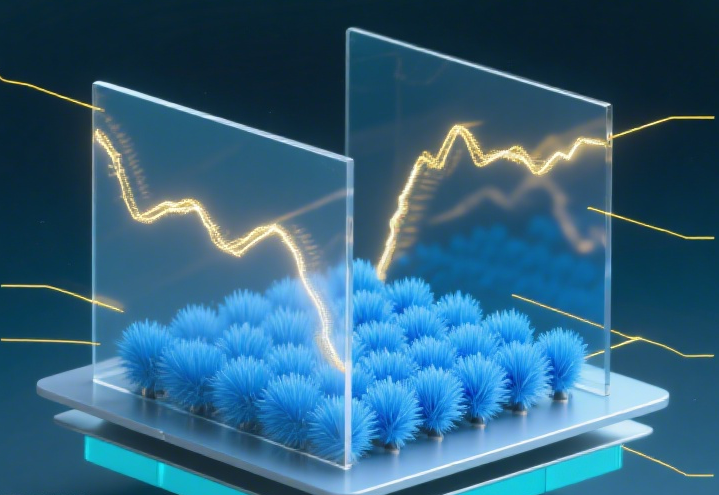

In conclusion, electrostatic flocking, traditionally used in largescale industrial fabrication, has recently regained attention as a fabrication method in the field of advanced functional materials. This resurgence is not only attributed to its low cost but also to its ability to create post-fabricated structures associated with advanced materials in emerging fields. These structures feature high aspect ratios and enable control over orientation to achieve various macroscopic and microscopic configurations, facilitating the alignment of structure and performance for diverse materials across different applications. Especially, the highly tunable orientation of fibers is feasible to adapt different performance in various applications. Firstly, controlling fiber orientation in electrostatic flocking enables the creation of porous structures with adjustable pore size, which enhance efficiency in applications such as tissue engineering and supercapacitors. Secondly, the classic vertical orientation gives rise to various anisotropic advantages, including enhancedelectrical conductivity, thermal conductivity, and wettability. Moreover, high-aspect-ratio fibers standing vertically on the substrate can significantly amplify their responsiveness and sensitivity to external stimuli. Additionally, the parallel fiber alignment amplifies the surface reflection through a “light-trap effect.” By regulating the orientation, the surface roughness can also be directly altered, leading to changes in surface friction. Lastly, oriented fibers can serve as a support layer within the material, thereby enhancing its tensile and compressive capacity along the axial direction of the flocked fibers.

However, electrostatic flocking still faces several challenges. 1) The adhesion of flocked fibers heavily relies on the adhesive applied to the substrate. The bonding strength of these adhesives critically influences the long-term structural stability of flocked f ibers during operational use.2) The vertical alignment precision and spatial uniformity of electrostatic flocked fibers remain inferior to other fabrication technologies such as 3D printing, particularly when the fibers are relatively long, as they tend to collapse or bend. Thus, the following suggestions are put out in light of recent research developments, as depict in Figure 14.

1) Exploration of new flocking materials: Currently, electrostatic flocking materials primarily focus on 1D fiber materials (like polymer fibers and carbon fibers) or nanotubes. Thus, other functional fibers, such as photo/thermo-responsive fibrous materials, or metal nanorods, could be explored to form array structures via electrostatic flocking, which might enable the f locked-materials to acquire new functionalities, such as soft robots inspired by flying insect muscles or light-tracking solar water evaporator inspired by sunflowers. Furthermore, it is worth investigating that only one study has reported that the boron nitride flakes were neatly arranged in the epoxy to enhance thermal conductivity. The array effect of BN, however, remains unsatisfactory. Whether better alignment structures of 2D flakes can be achieved through electrostatic flocking by adjusting the surface charge distributes of 2D flakes is to be investigated.

2) Exploration of new flocking structures: current reported flocking materials are limited to the pattern where the flocked fibers randomly stand on a flat substrate through adhesives. In other words, the geometry of the flocking substrate is constrained, and while the orientational order can be controlled, achieving positional order remains unattainable. However, many natural villus structures, such as those found on the human nasal, dandelion, or cilia in the human respiratory tract, feature surfaces with different curvature. These examples inspire the exploration of the possibility of flocking fibers onto curved surface or inner surface of cylinders. Additionally, adjusting the pattern of adhesive also could provide the substrate more intricate patterned designs.

3) Exploration of new applications: different villus structures typically imply different functions and applications. Integrating functional flocking materials with flocking structure with unique patterned designs, more natural fluffy structures, can potentially be replicated, achieving more outstanding performance in biomimetic and other functional applications. For example, the fluffy structure of dandelions can be mimicked using electrostatic f locking to prepare microfliers. Utilizing electrostatic flocking to create a directed inclined array may simulate the domino-like photonic nanostructures on butterfly wings, achieving the effect of structural color. Electrostatic flocking may also be utilized to mimicthestructure of thesmall intestine withmicrovilli ona macroscopic scale, allowing for allergy simulation in a realistic environment. It has the potential to be developed as a cellular sensor.

[114] Copyright © 2024 The Author(s), exclusively licensed by Springer Nature Limited. Reprinted with permission.

[115] Copyright © 2024 Wiley-VCH Verlag GmbH & Co. KGaA. Reprinted with permission.

[116] Copyright © 2019 American Chemical Society. Reprinted with permission.

[114] Copyright © 2024 The Author(s), exclusively licensed by Springer Nature Limited. Reprinted with permission.

[117] Copyright © 2009 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. Reprinted with permission.

[118] Copyright © 2021 Elsevier B.V. All rights reserved. Reprinted with permission.

[119] Copyright © 2019 Elsevier Ltd. All rights reserved.

References:

[114] Zhao, Y., Liu, Z., Shi, P., Chen, C., Alsaedi, A., Yan, Y., He, X. Nature Materials 2025, Vol. 24.

[115] Tian, L., Han, L., Wang, F., Shen, H., Li, Q., Zhu, L., Chen, S. Advanced Energy Materials 2024, Vol. 24.

[116] Liu, Y., Li, F., Qiu, L., Yang, K., Li, Q., Zheng, X., Hu, H., Guo, T., Wu, C., Jin, T. ACS Nano 2019, Vol. 13.

[117] Kustandi, T. S., Low, H. Y., Teng, J. H., Rodriguez, I., Yin, R. Small 2009, Vol. 5.

[118] Jiang, D., Sheng, K., Jiang, H., Wang, L. Bioelectrochemistry 2021, Vol. 142.

[119] Yin, H. J., Kim, D. H., Choi, W., Khan, U., Kim, T. Y., Kim, T., Kim, S. W. Nano Energy 2019, Vol. 63.

Excerpt from the paper "Electrostatic Flocking: Reborn to Embrace Multifunctional Applications"